| brand |

not have |

origin |

domestic |

| Customized processing |

deny |

|

|

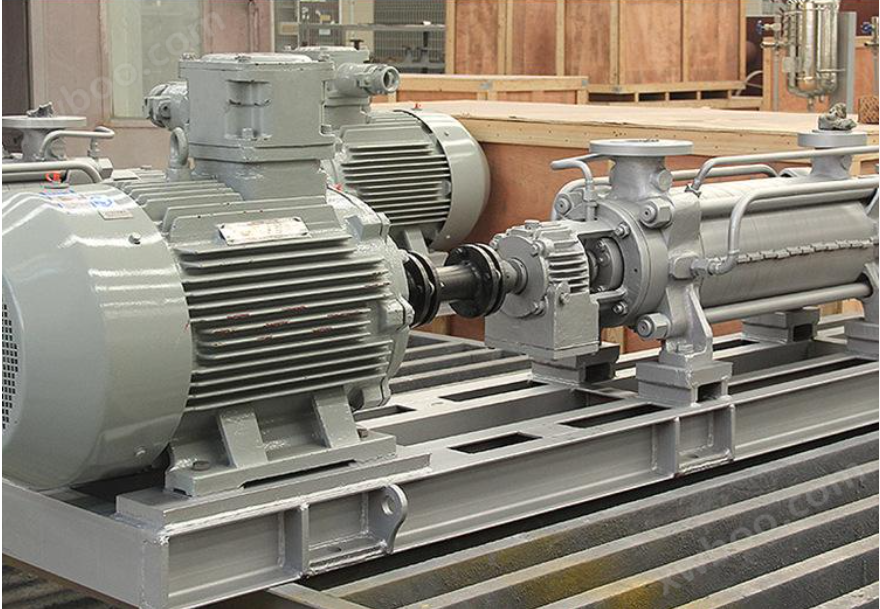

BB4 Two end supported multi-stage radial separation heart pump

Oil and Weather

petrochemical industry

Pulp and Paper Manufacturing

Boiler feedwater below 210 ℃, combined cycle power plants

Solar energy utilization, biological and industrial power plants

BB4 Two end supported multi-stage radial separation heart pump

Oil and Weather

petrochemical industry

Pulp and Paper Manufacturing

Boiler feedwater below 210 ℃, combined cycle power plants

Solar energy utilization, biological and industrial power plants

High pressure water pump for general industry

BB4 Two end supported multi-stage radial separation heart pump

Design features:

Flanges comply with ANSI/DIN/ISO standards

The dimensions of the mechanical seal chamber comply with ISO21049 (API682)

Several different hydraulic models have been designed for each specification of the impeller to ensure high efficiency and low operating costs over a wide operating range. The first stage double suction impeller structure can be used for low NPSHa operating conditions

The shell adopts a central support form to withstand high forces and moments

According to the working conditions of power and axial force, self-lubricating and sliding bearing thrust pad bearing designs can be selected, and additional lubricating oil systems can be chosen

The balance drum and axial thrust bearing can operate for a long time under harsh usage conditions

Design parameters:

Q=15...1000m3/h

H=180...2600m

-

T=-80℃~+220℃

It is due to the pressure in some local low-pressure areas near the inlet of the liquid channel decreasing to the saturation vapor pressure of the liquid, resulting in partial vaporization of the liquid. So, any factor that can reduce the local pressure to the vaporization pressure of the liquid may be the cause of cavitation. The conditions for cavitation should be considered from three aspects: the characteristics of the suction device, the structure of the pump itself, and the properties of the liquid being transported.